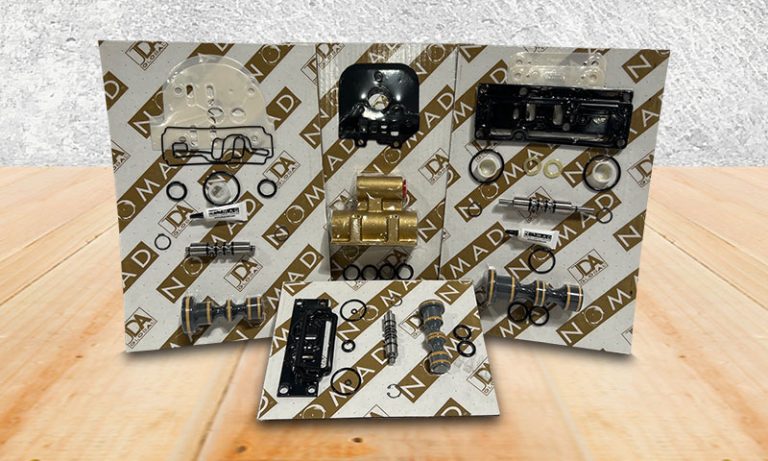

U-cups, also known as lip seals, play a pivotal role in pump systems, specifically in the seating area for robust applications. This design is particularly employed in demanding scenarios where resilience is paramount. As application pressure increases, the seal’s distinctive “U” shape, or lips, becomes energized, enhancing the seal’s effectiveness. U-cup products are versatile, available in the same materials as mentioned in the ball and diaphragm sections, with the choice determined by the characteristics of the media being transferred.

What are U-Cups in Pump Systems?

U-cups, or lip seals, are specialized components utilized in the seating area of pump systems, especially in applications demanding robust performance. The design, characterized by a “U” shape, is chosen for its resilience. As pressure increases during application, the U-cup’s unique shape energizes the seal or lips, optimizing their sealing capabilities. These products are adaptable and available in various materials to suit the requirements of different media being transferred.

How Do U-Cups Contribute to Pump Functionality?

U-cups contribute significantly to the functionality of pump systems by providing a robust sealing solution in challenging applications. The energizing effect of the “U” shape becomes pronounced as pressure increases, ensuring a reliable and effective seal. The versatility of U-cup products, available in materials matching those used for balls and diaphragms, allows for customization based on the specific characteristics of the media being transferred.

Applications of Pumps with U-Cups

- Robust Sealing in Demanding Applications: Pumps equipped with U-cups are designed for applications where robust sealing is essential. The unique design and energizing effect make U-cups particularly well-suited for challenging scenarios where dependable sealing capabilities are crucial.

- Adaptability to Varied Media: The availability of U-cups in materials matching those used for balls and diaphragms enhances their adaptability to varied media. Pumps featuring U-cups can be customized based on the specific properties of the transferred media, ensuring compatibility and optimal performance.

- High-Pressure Environments: U-cups excel in high-pressure environments where their energizing design comes into play. These seals are particularly effective in maintaining integrity and preventing leaks under elevated pressures, making them suitable for a range of industrial applications.

In conclusion, U-cups are integral to pump systems, providing robust sealing solutions for demanding applications. Their energizing design and adaptability to various materials make them versatile and effective in high-pressure environments. Pumps featuring U-cups offer reliability and customization options, meeting the specific needs of diverse industries.