Air diaphragm pumps are widely used in a variety of applications due to their versatility. Air operated double diaphragm pumps feature few moving parts, with no motor, base plate or other peripherals required. The design style, coupled with its positive displacement functionality, allows for the transfer of shear sensitive products with self-priming up to 25 feet. Air diaphragm pumps feature low initial investment as well as low replacement costs for wear parts when compared to other pump types.

Choose which type of Diaphragm pump you’re looking for.

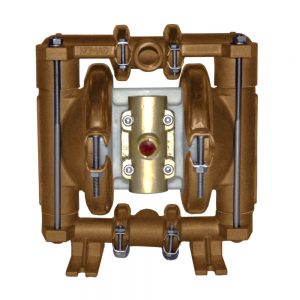

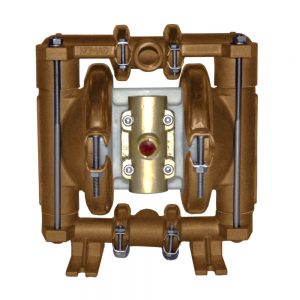

The TRANS-FLO gold product line features a rugged anodized aluminum piston-style air valve system, capable of functioning in the harshest compressed air conditions, emphasis on mining, construction and utilitarian applications. The TRANS-FLO GOLD system also features the fewest moving parts in the diaphragm pump business, allowing for ease of maintenance, assembly and disassembly.

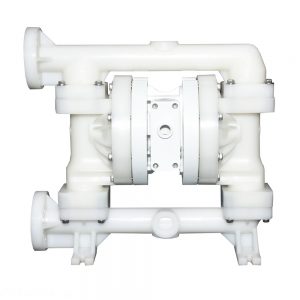

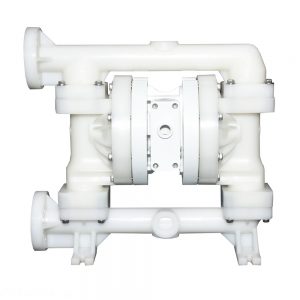

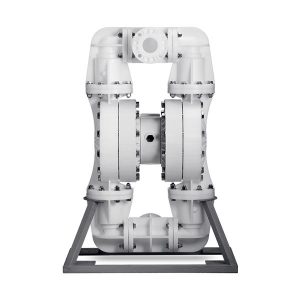

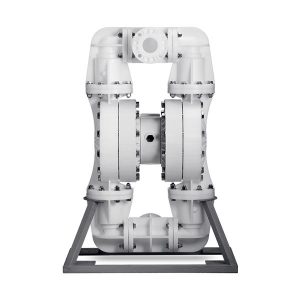

The PWR-FLO asymmetrical spool design (ASD) features the most efficient air system available. The anti-stalling design also provides excellent reliability in on/off liquid transfer for filling and batching applications. The air valve and center section is made of chemically resistant polypropylene.

The OPTA-FLO product line includes the ½” polypropylene and 1” aluminum pump, respectively. These units are considered “specialty pumps” used primarily in lube stations and oil field truck applications. The reliable and proven air valve design has led to a large worldwide installed base via the OEM, a market leader. Each unit features a bolted design with multiple elastomers options. These models are 100% retrofittable to the OEM models.